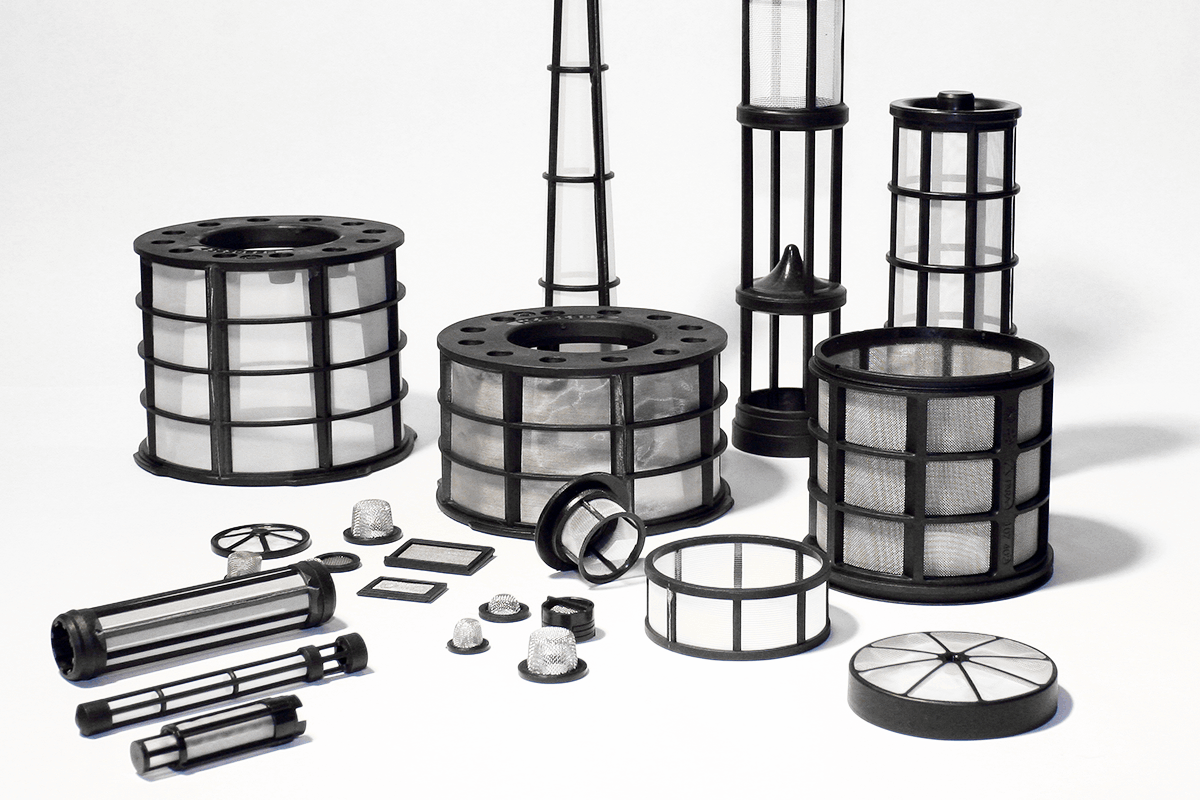

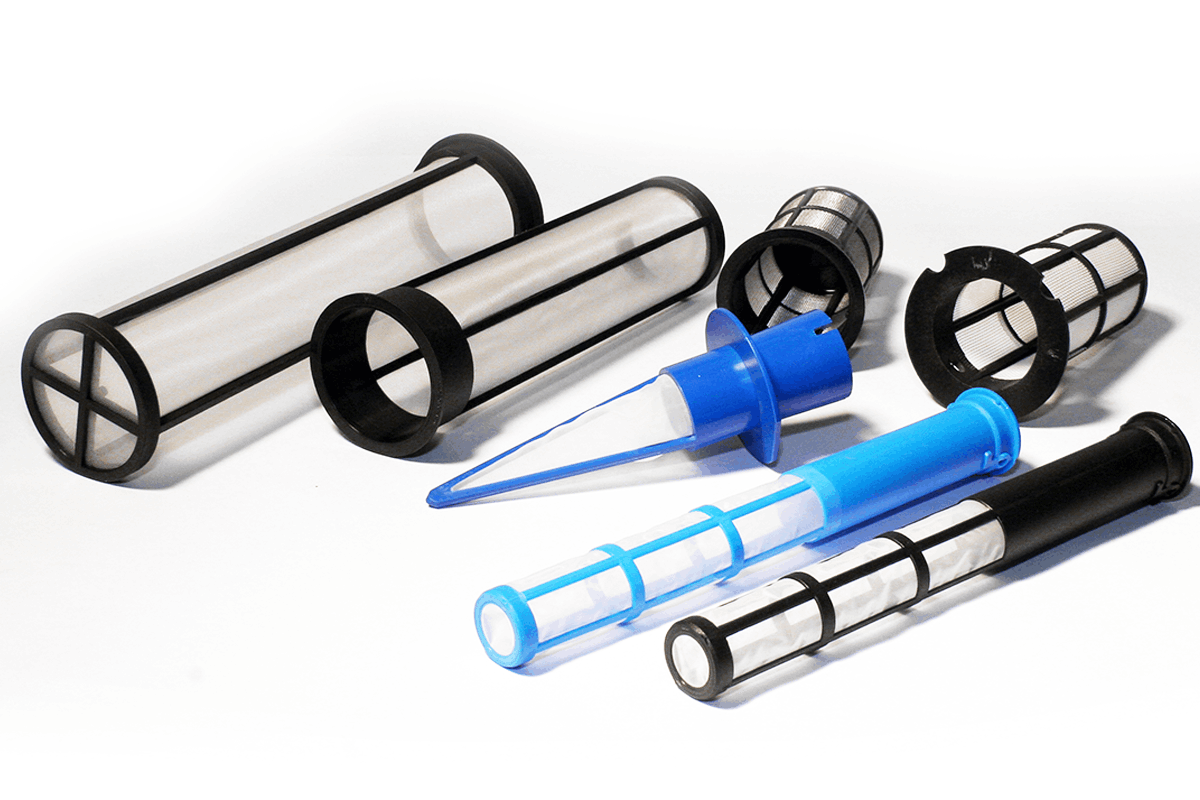

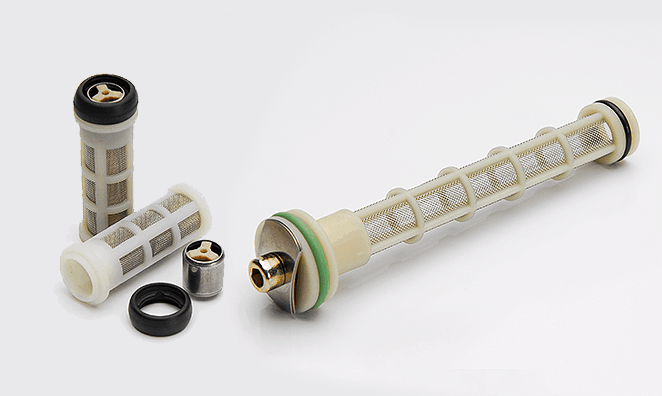

Screen Filters for Various Drinking Water Applications

Stainless steel mesh and plastics approved for drinking water (for example according to KTW, WRAS, etc.) are used for dirt strainers and fine filters in the drinking water sector, mainly POM, POM-GF30, PP, PP-GF30, TPE.